Quality

Our double vision inspection system, comprising over 150 cameras, is utilized for the visual detection of defects and foreign objects within nonwoven fabric. The material is inspected at 3 different levels throughout the production process (winder, slitter before cutting, slitter after cutting) to maximize the detection performance. Latest upgrades include the ability eliminate defects by color, while most vision systems only detect black and white shades.

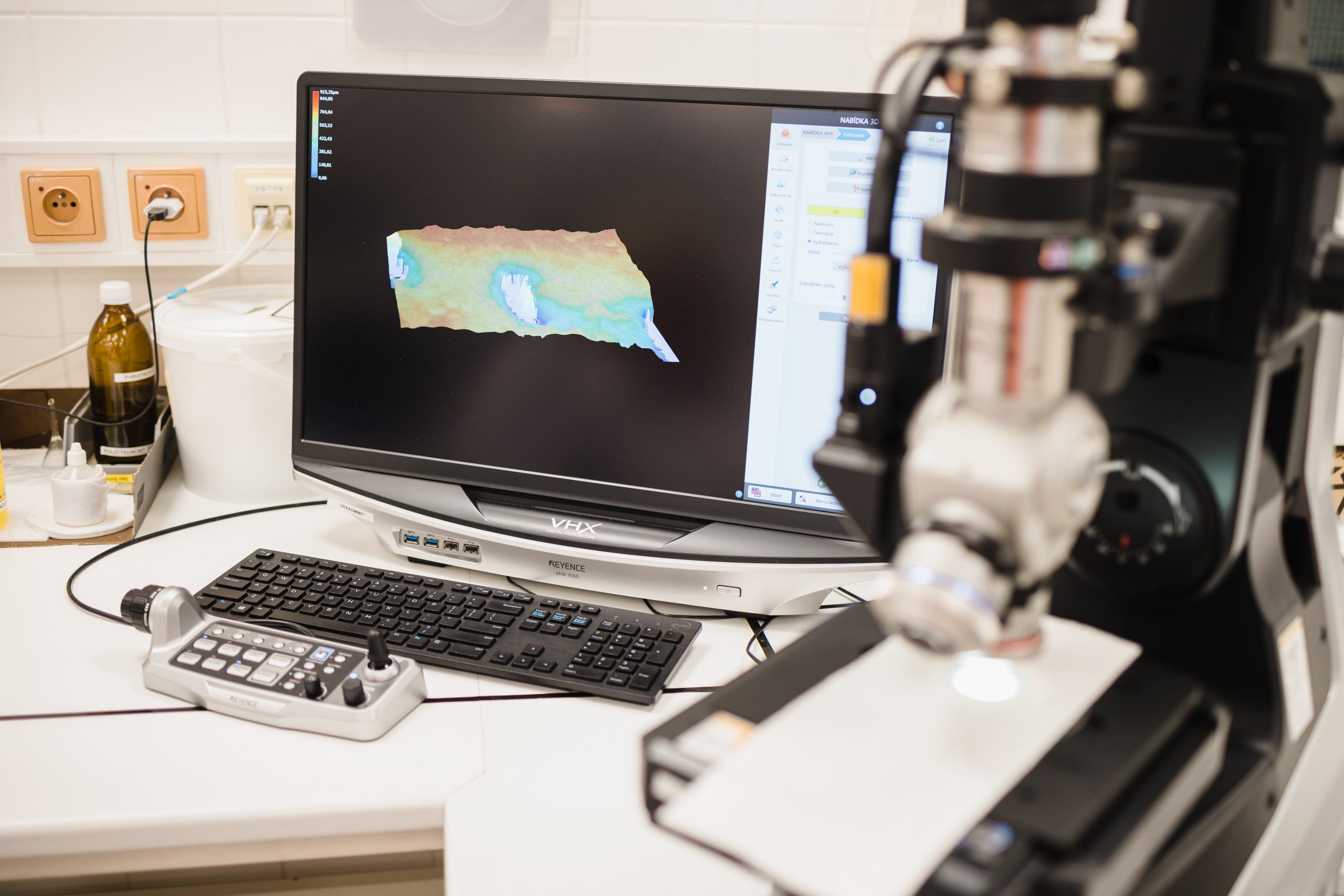

Our laboratory is furnished with an extensive array of performance testing technology. We provide our partners with every collected data point and conduct various types of testing to optimize performance for end-consumers while maintaining competitive pricing. Our testing capabilities include abrasion and pilling, melt flow, tensile strength, and filament diameter and structure analysis using advanced digital microscopes such as KEYENCE VHX or scanning electron microscope TESCAN VEGA3.

To fulfill requirements of strict hygiene standards, our facilities are equipped with Positive Air Pressure System. It is designed to prevent the entry of contaminants, such as bacteria, dust, and other airborne particles, into the controlled environment. By maintaining a higher pressure inside the clean room, any leaks or gaps in the room’s construction will allow air to flow out of the clean room rather than in, preventing the entry of contaminants

PFN has developed a robust hygiene standards inside our production facilities.Our Double Door System ensures both door cannot be opened simultaneously, preventing any impurity in our materials or a possible unwanted entry. To prevent rodent infestations, we have installed three levels of traps inside and outside our production facilities. To eliminate any insects we have installed a network of UV lamps inside and outside our factory.